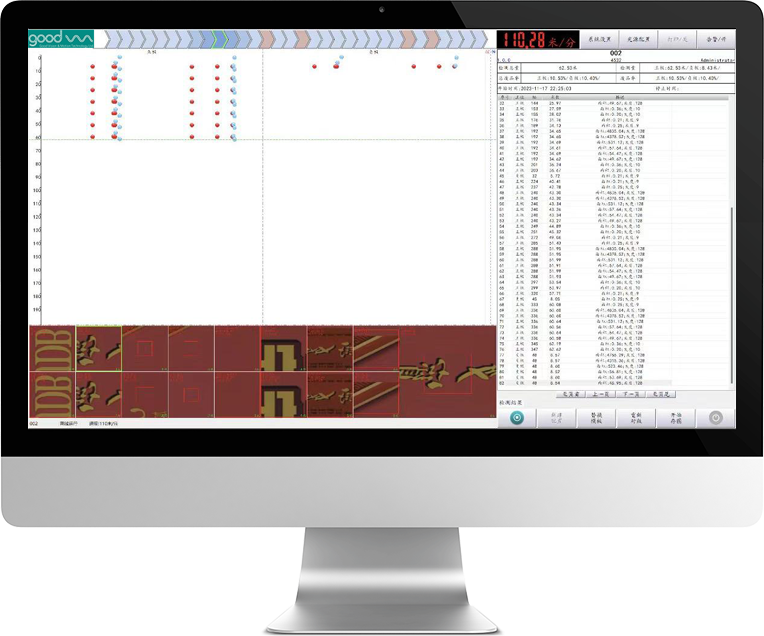

Humanized operation interface, clear detection information at a glance

Simple and fast modeling, supporting single-sided and double-sided detection, simplifying modeling steps, one click modeling, easy to operate

The defect classification is precise and typical, which can directly meet the printing production needs, as well as name and define defects according to user needs

A high-speed detection algorithm with multiple defect filtering, fully realizing fast detection without missed detections