Quality control software

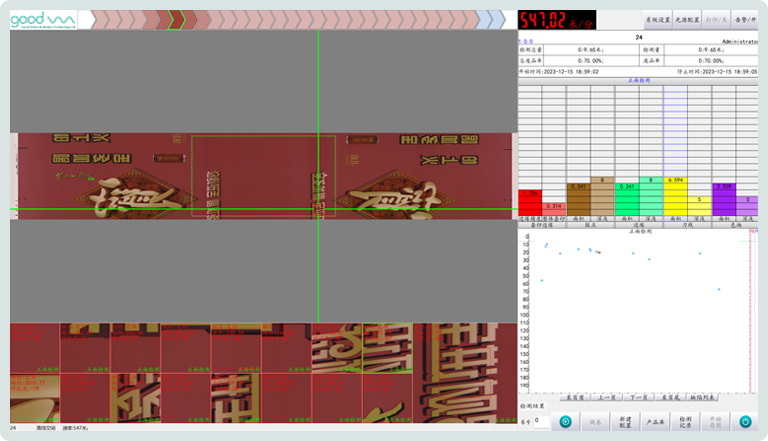

GoodVisionUI (Printing Quality Inspection Software)

The GoodVisionUI printing quality detection software adopts high-speed image processing algorithm research, multi-core and multi-threaded. On the basis of traditional image algorithms, customized development is carried out for hundreds of defects. AI is used to enhance image learning and prediction capabilities, and intelligent classification processing is carried out for defects. The detection software compares real-time images with standard template images, supporting the detection of various types of defects such as overprinting, dirty spots, cutting edges, color differences, and missing text. On the interface of the detection software, the detected defects can be displayed in real-time on the defect wall, and the defect image can be enlarged and compared with the standard image. The operator can view, delete, or mask negligible defects in real-time. The system will record and store all defect types, locations, and strength parameters.

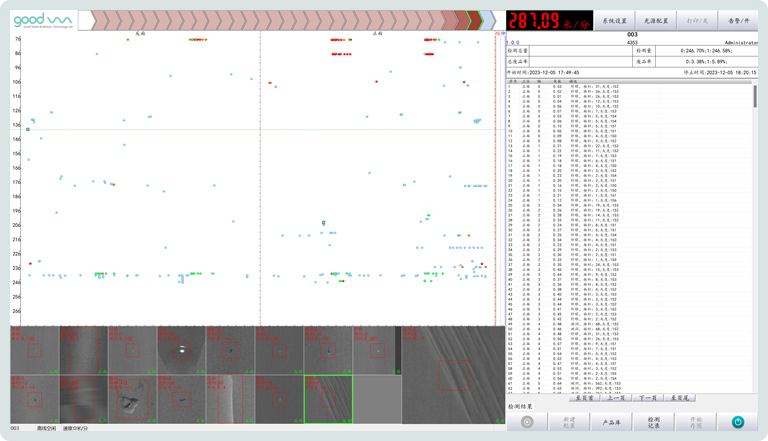

GoodVisionMetalFoil

The GoodVisionUI printing quality detection software adopts high-speed image processing algorithm research, multi-core and multi-threaded. On the basis of traditional image algorithms, customized development is carried out for hundreds of defects. AI is used to enhance image learning and prediction capabilities, and intelligent classification processing is carried out for defects, including convolutional scanning, pooling, feature data flattening, self-learning, false defect filtering, intelligent prediction, etc. At the same time, the software can also analyze, count, store, and trace detected defects.