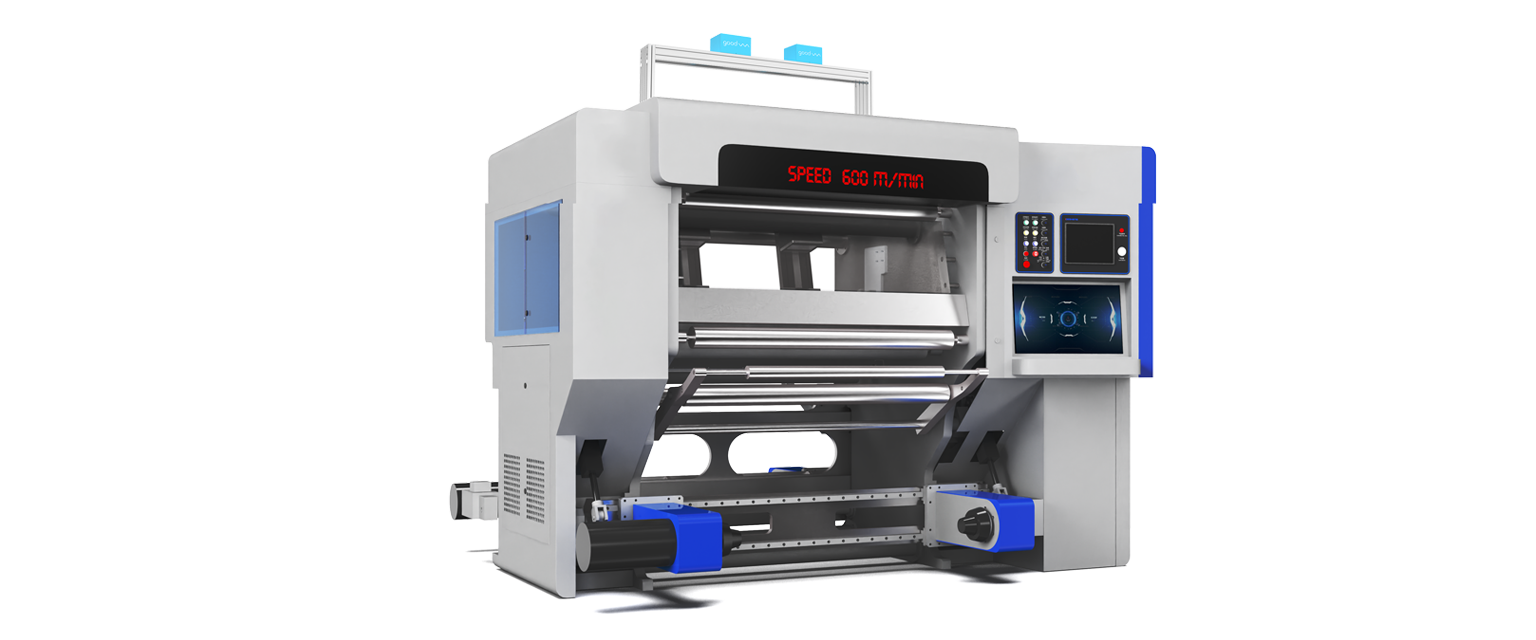

Defect removal: System detection combined with manual screening, controlling the machine to reverse and remove defects

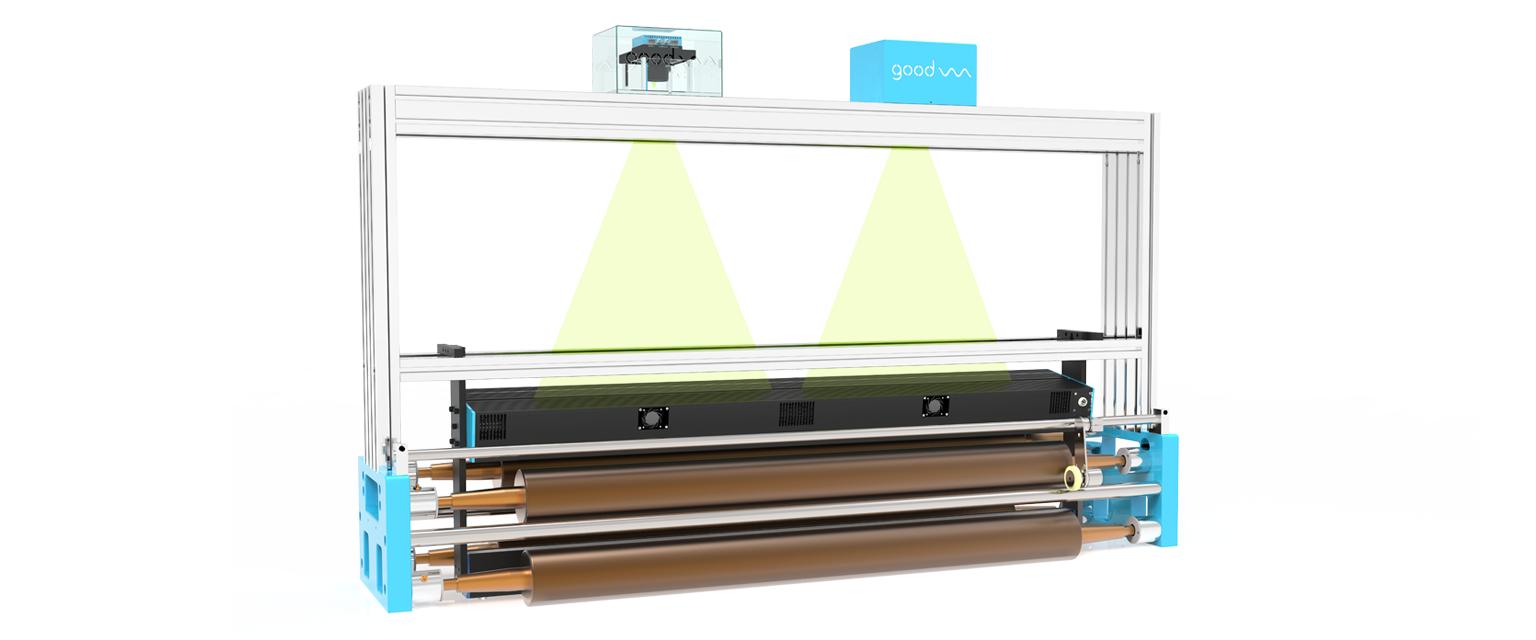

High image acquisition line frequency: up to 60K

Intelligent classification processing: using AI to enhance image learning and prediction capabilities

High stability light source: bright intensity, good uniformity, and long service life